GEN II Fertilizer System

The latest and most versatile of the Montag dry fertilizer metering systems is Generation Two (GEN II). It was developed in response to customer inputs but maintains most all of the features of the Montag Generation I metering system which has made Montag the standard of the dry fertilizer banding industry. With its ability to add rows and configure drives you can now easily invest in a metering platform that can be adapted to your operation as it changes and evolves for years to come.

Features

High quality injection molded HDPE plastic augers

- Very accurate metering with large rate range (25lbs. – 500lbs. per tank). See capacity chart for details.

- No need to change metering drive for full rate range – unlike other competing brands.

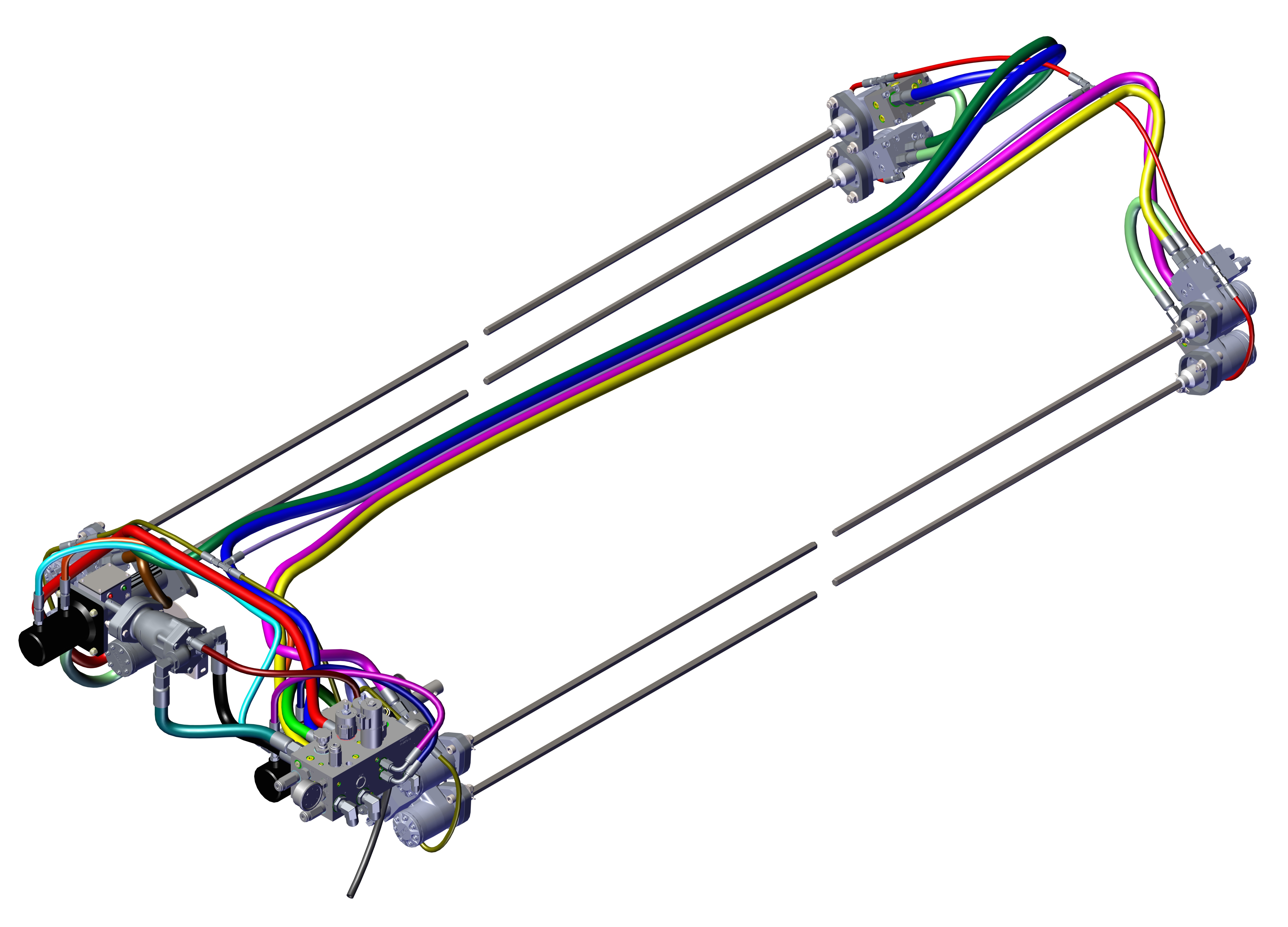

Single Hydraulic Input requirement

- Reduces hydraulic requirements allowing for more options for grower

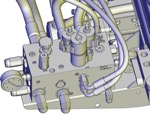

PWM Hydraulic Block Standard

- The Montag specific hydraulic block allows for industry leading control of the product metering system and the fan with only one hydraulic bank required. The block includes safety valves to protect the fan seals and reduces heat in the hydraulic system.

Sealed Tank

- Tank is sealed to maintain air pressure between bins for greater row to row accuracy.

- Simple yet rugged designed tank & lid seal, using automotive rubber gasket.

ISOBUS Rate Controller

- Specifically developed to operate GEN II system with full functionality.

- Compatible with most of the industries displays – Contact Montag representative for more information.

ISOBUS Scale

- GEN II’s come standard with each tank being mounted to the frame with an ISOBUS scale.

- ISOBUS scales are integrated into the GEN II Montag rate controller.

Tank Ladder Access

- The rear deck can be configured for the ladder to be mounted for a left or a right-hand entrance.

- Additionally, ladder can be ordered with a rear access.

Improved Montag Fluid Bed – GEN II Air Delivery System

- GEN II air system is streamlined to improve aerodynamics and reduce horsepower requirements.

- Fertilizer is introduced into the air stream at the air chamber, requiring less pressure to move it to the row unit.

Components are corrosion resistant

- Any component that comes in direct contact with fertilizer is either stainless steel or plastic.

- Components outside the tank (such as Valves / Weigh bars / Elec. Harnessing) are all selected with our corrosive environment in mind for in-field reliability.

Up to 4 section configurations

- Sections can be added to the GEN II system at any time – giving you added flexibility.

- Sections are controlled with hydraulic motors and PWM valves for infield reliability.

Tank Design

- The GEN II comes with two 4.5-ton (US) tanks with a built-in walk way that divides the tanks and built-in steps for accessing the inside of the tank.

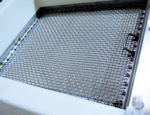

Screen Design

- Screens are positioned with a 7-degree angle to help fully fill the tank by driving the fertilizer to the outside of the tank when filling.

- 2018 GEN II’s and newer will include a full set of (2) ½” screens and (4) ¾” screens.

- Removes large materials when loading that can plug down tubes or can harm metering system.

Options

Up to 4 section configurations

- Sections can be added to the GEN II system at any time – giving you added flexibility.

- Sections are controlled with hydraulic motors and PWM valves for infield reliability.

Screen Size

- Available in ½” or ¾” screen to size product so as to reduce blockage in either the auger or the injection tube (behind the knife on the toolbar).

- Screens are constructed completely out of stainless steel.

- 2018 GEN II’s and newer will include a full set of (2) ½” screens and (4) ¾” screens.

Rear Deck & Ladder

- The rear deck can be configured for the ladder to be mounted for a left or a right-hand entrance.

- Additionally, ladder can be ordered with a rear access.

J. Assy Fertilizer Sensor